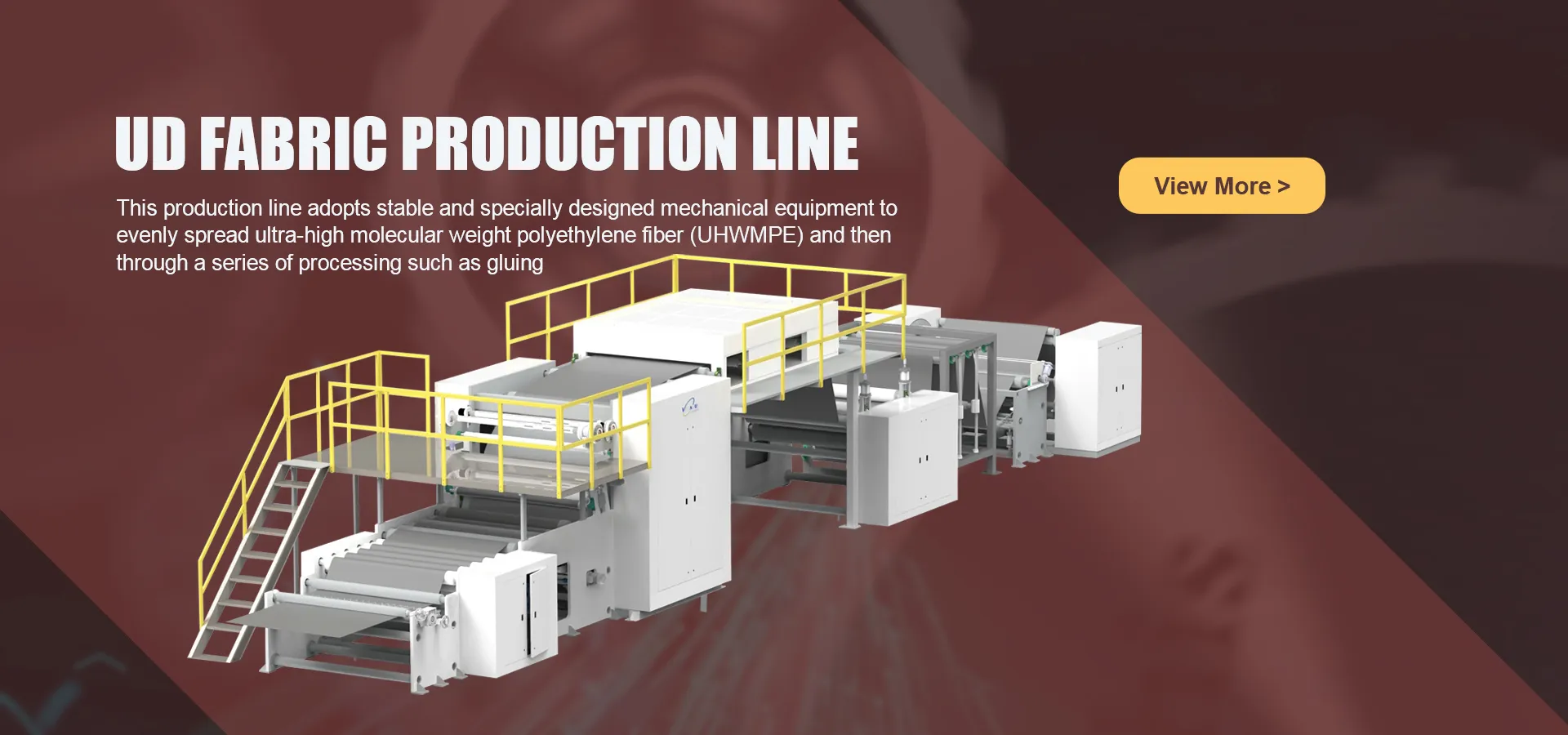

The Difference Between PUR Hot Melt Adhesive Laminating Machine and Water Base Adhesive Laminating Machine

What is the difference between the film forming property of hot melt adhesive laminating machine and water-based adhesive laminating machine? This time we will analyze the difference between the two through modeling.

Water-based adhesive compounding machine is made of water-based adhesive or natural rubber. Integral coating, low wash-ability.

Polyurethane adhesive is mainly used in clothing, automotive interior, home textiles, industry.

Hydraulic adhesive compound machine is mainly used in shoes and hats, fiber, luggage, car interior, carpet and other industries.

The oil binder laminator mainly transfers the polyurethane adhesive to the cloth in the form of dot.

It has the advantages of good firmness, washing resistance, softness, strong air permeability and no deformation.

Waterborne adhesive is different from waterborne coating adhesive.

Acrylic or polyurethane resins are emulsified with water as solvent through a special emulsifying device.

Its advantage is breed much, environment is friendly, the price is cheap, paint has a lot of water-soluble adhesive, be like water-soluble PA, water-soluble polyurethane and leather adhesive, tramp wax, shave shave the functional medicine ointment such as cream.

Water-soluble coatings will become the development direction of coatings in the future because of their functionality, environmental protection and low price.

Disadvantages are poor film forming, poor washable, and polyurethane can not be stuck in the hot gas sol.

The oil coating adhesive is prepared by dissolving acrylic acid or polyurethane in an oil solvent (toluene, DMF, butane, etc.).

Its advantages are good film forming, good firmness, polyurethane sticky hot air adhesive is currently widely used paint adhesive.Disadvantage is the use of solvent oil, so the environment is not high. In particular, the price of petroleum solvents continues to rise.

Most paints are expensive and the solvent oils used are of poor quality, which is not enough to protect the environment.

In addition, with the further improvement of environmental protection standards in various countries. Therefore, the environmental requirements of paint adhesive are becoming higher and higher.

Hot melt adhesive composite machine mainly continues to be coated on water-based rubber, used for winding composite materials, washing strength is not high.

Mainly used in clothing, automotive interior, textile, industry, water adhesive and other industries, mainly used in shoes and hats, textile, luggage, automotive interior, carpet and other industries.

The fabric is transferred to other fabric layers mainly in the form of polyurethane adhesives. It has the characteristics of good water resistance, washing resistance, softness, strong air permeability and no deformation.

The difference between adhesive and hydrogel calendering machine is that water-based coating adhesive is made of water-based solvent and acrylic or polyurethane resin emulsified by special emulsifying device.

This composite material has the advantages of uniform coating, surface composite, no stretching deformation, no stretching, foaming, wrinkling, soft, breathable, clean, thin, washing, suitable for fabric stickers, wool stickers, fabric P, etc. (such as leather, foil, spandex).

Different from the establishment of diplomatic compound machine, hot melt compound machine is an important aspect of electrical safety, non-professional electricians can not open the electrical box for maintenance, wiring, maintenance and so on to strictly abide by the electrical safety operating procedures.

Otherwise it could cause electric shock or fire. In case of fire, the power supply must be cut off immediately and dry powder fire extinguisher must be used to extinguish the fire.

If someone is electrocuted, rescue him or her according to the electrical operation regulations and send him or her to the hospital.

Cabling and operation must be carried out in strict accordance with instructions.

Otherwise, the equipment may be damaged (due to the partial power supply of the equipment, the motor driver may be single-phase 220 v AC).

Persons operating and maintaining equipment should take appropriate measures for their own safety.

They must wear sleeves, cotton, overalls and gloves. If you burn yourself, apply hot cream immediately.The injury is serious and must be taken to hospital immediately after application of hot ointment.When applying adhesive to skin, do not remove it or soak it in water.

.webp)