Continuous Production Line for UD Weft-Free Fabric: The “Hardcore” Support Behind Bulletproof Vests

14 Apr

14 Apr

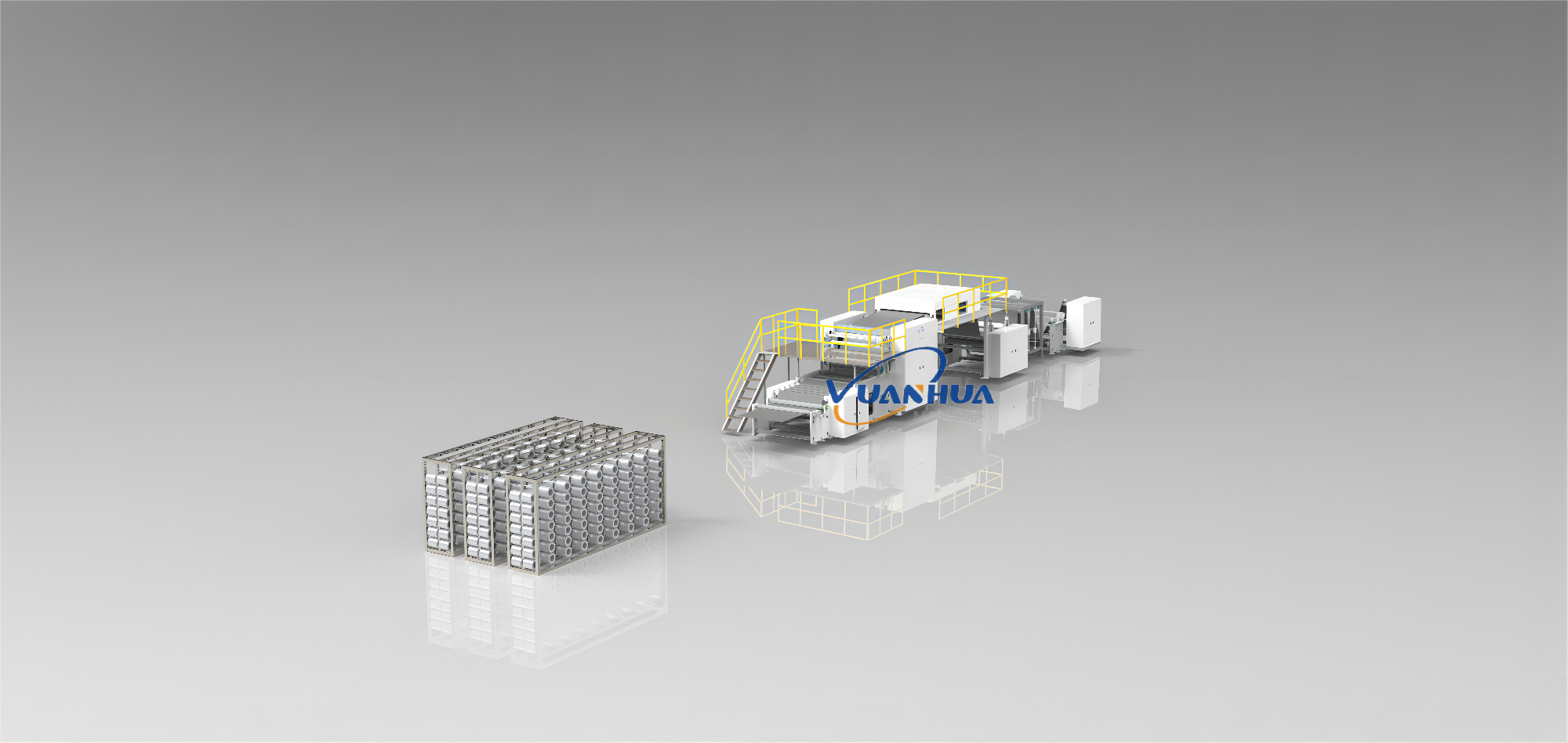

In the field of safety protection, bulletproof vests serve as a critical line of defense for life safety. The continuous production line for UD weft-free fabric by Yuanhua Equipment is bringing a revolutionary change to the performance of bulletproof vests. The UD weft-free fabric produced by this line boasts an exceptionally high strength-to-weight ratio. Its unique fiber arrangement ensures that every high-performance fiber fully withstands and distributes force when subjected to impact. When a bullet hits a vest, the UD weft-free fabric rapidly disperses the impact energy, effectively blocking penetration and significantly enhancing the vest’s protective capability.

From a manufacturing perspective, the continuous production line for UD weft-free fabric features remarkable stability and precision. With precise temperature control between 120–160°C, it ensures tight and uniform bonding between fibers during the material lamination process. Advanced equipment such as the UD fabric hot-press laminating machine works in tandem to perfectly composite materials with different functions, improving overall protective performance. The computerized cutting machine accurately tailors the fabric according to the vest’s design, minimizing waste and boosting production efficiency.

In practical applications, bulletproof vests made from UD weft-free fabric produced by this line provide reliable safety for law enforcement and military personnel. Traditional vests are often heavy and restrictive, hindering mobility. In contrast, UD weft-free fabric vests maintain high protection levels while reducing weight significantly, offering greater comfort and flexibility. This allows wearers to act more agilely during missions. As the production line technology continues to advance, the performance of UD weft-free fabric is constantly being optimized, promising further improvements in both protective capabilities and wearing experience.