The Hazards of Dust and Impurities to PUR Hot Melt Glue Laminating Machines and Solutions

12 Jun

12 Jun

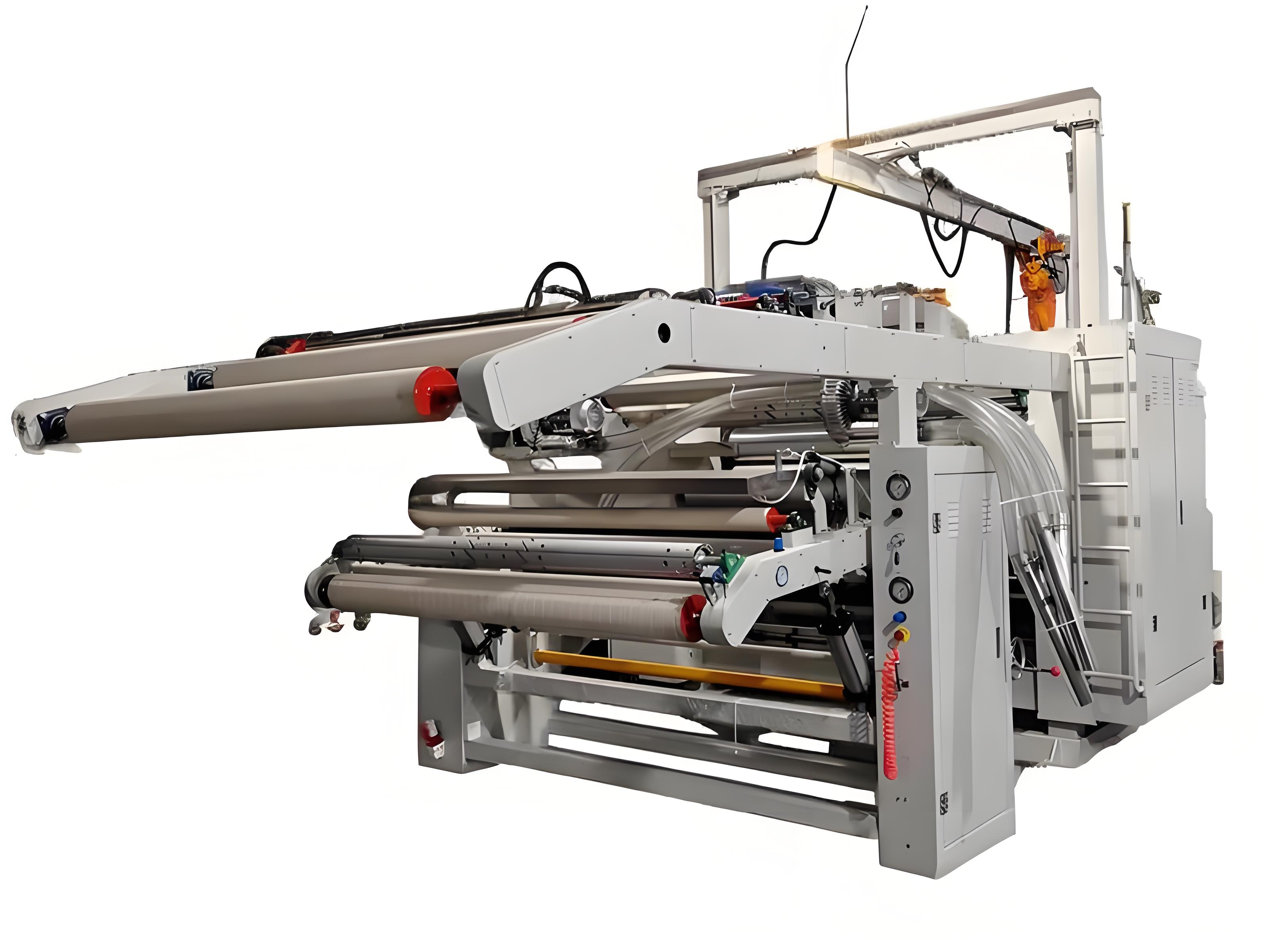

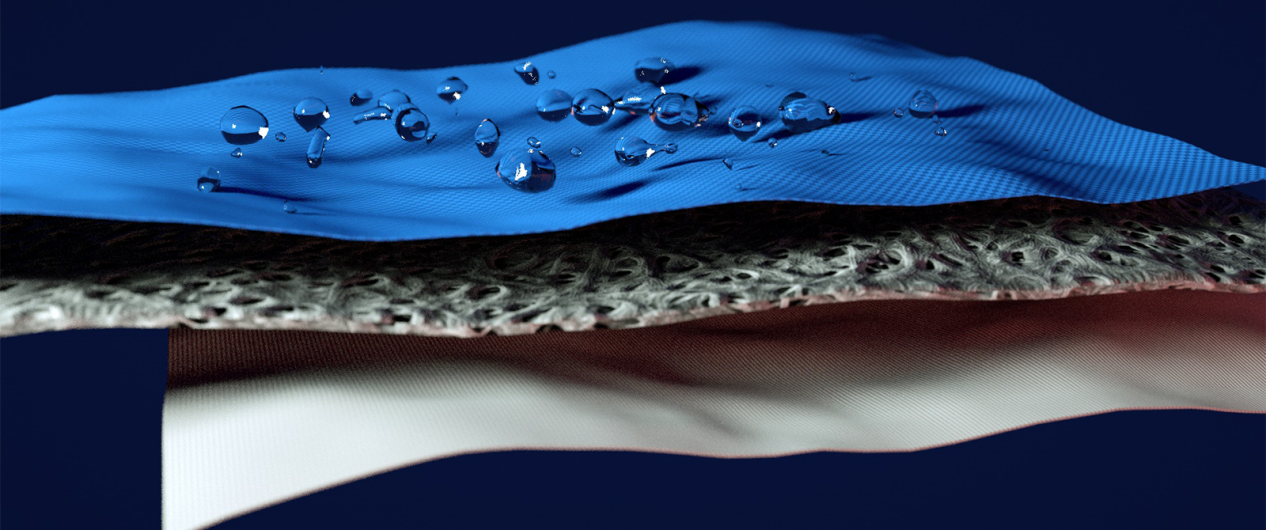

In the modern industrial manufacturing system, PUR hot melt glue laminating machines occupy a crucial position in fields such as electronic manufacturing, packaging & printing, automotive interiors, and garment processing due to their excellent performance. However, the complex industrial production environment harbors hidden dangers, among which the intrusion of dust and impurities has become a key factor affecting the stable operation of PUR hot melt glue laminating machines and product quality. This article systematically discusses the potential threats of these tiny particles and proposes targeted scientific and effective countermeasures.

Dust pollution in industrial production scenarios exhibits multi-source characteristics. In raw material processing links, processes such as cutting and grinding release large amounts of solid particles; when mechanical equipment operates, high-speed rotating components like anilox rollers and rubber rollers agitate the air, causing tiny particles to suspend and diffuse; frequent personnel flow and fiber shedding from work clothes are also non-negligible pollution sources. These ubiquitous dust and impurities, like invisible "industrial killers," quietly threaten the normal operation of PUR hot melt glue laminating machines.

When dust and impurities invade the interior of PUR hot melt glue laminating machines, a series of chain reactions will be triggered. From the perspective of equipment structure, core components such as heating plates, scrapers, and anilox rollers bear the brunt. Dust adhering to the surface of the heating plate forms a thermal insulation barrier, interfering with uniform heat conduction, causing local overheating, and accelerating component aging; hard impurity particles directly scratch the heating plate, damaging its surface finish and shortening its service life. As key components for precisely controlling the glue coating amount, once affected by dust and impurities, the scraper and anilox roller will lead to uneven pressure distribution and coating gaps, resulting in inconsistent glue coating thickness. Long-term frictional wear will further reduce coating accuracy, affecting product appearance and quality. In addition, when the laminating roller presses materials, if its surface is contaminated with dust and impurities, it will destroy the uniformity of the pressing force, causing loose material bonding, while aggravating the surface wear of the laminating roller, resulting in an uneven roller surface and seriously affecting the stability of the laminating process.

To effectively address the challenges posed by dust and impurities, a systematic protection system needs to be constructed. In terms of environmental governance, high-efficiency dust removal equipment such as pulse bag dust collectors and cyclone separators can be installed to purify the workshop air in real time; strict cleaning regulations can be formulated to regularly clean the ground and wipe equipment to maintain environmental cleanliness; the workshop ventilation system can be optimized to form air convection and reduce dust concentration. At the equipment maintenance level, a regular in-depth maintenance mechanism should be established to professionally clean components such as heating plates, scrapers, and anilox rollers to remove stubborn stains and impurities; precision instruments should be used to detect the contact pressure between the scraper and anilox roller to ensure they are in the best working condition; close attention should be paid to the wear condition of the laminating roller, and damaged components should be replaced in a timely manner. In terms of operation management, standardized operation procedures should be formulated, requiring operators to strictly follow the specifications in links such as equipment start-stop, material replacement, and parameter adjustment—for example, 严禁 (strictly prohibiting) operations when the equipment has not completely stopped running, and handling materials gently to reduce the risk of dust raising.