PUR Hot Melt Glue Laminating Machine Quality Identification Guide: Analysis of Multi-dimensional Evaluation System

![PUR Hot Melt Glue Laminating Machine Quality Identification Guide: Analysis of Multi-dimensional Evaluation System]() 12 Jun

12 Jun

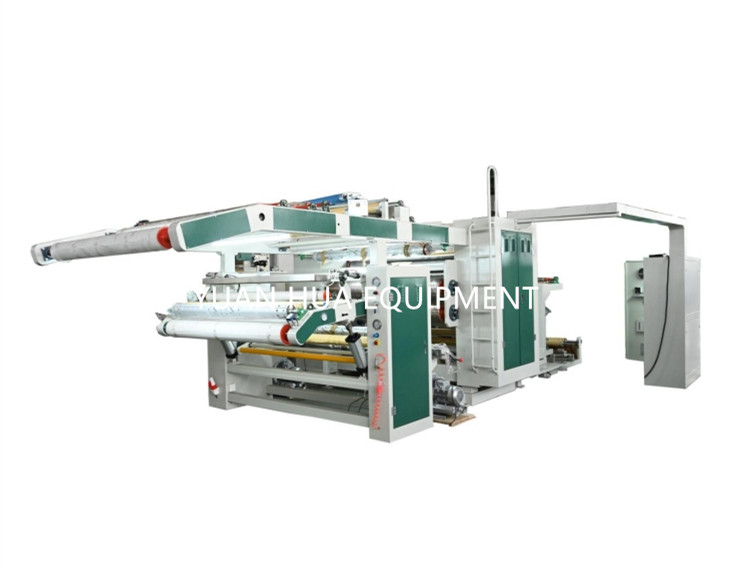

In the field of high-end material lamination, the quality of PUR hot melt glue laminating machines directly affects product quality and production efficiency. Its quality evaluation needs to be carried out from multiple dimensions. The following are the core judgment points:

- Appearance & Craftsmanship: High-quality PUR laminating machines feature uniform spraying without defects, reflecting exquisite workmanship.

- Key Components: Critical parts such as the hydraulic glue supply system and dynamic mixing device are made of special alloys, processed and heat-treated with precision. For example, high-precision coating rollers undergo mirror finishing and wear-resistant coating, with cylindricity error controlled within the micrometer level to ensure coating stability.

- Operation Stability: After startup, the machine should run smoothly with low noise.

- Glue Supply Stability: As PUR glue is sensitive to temperature and pressure, high-quality equipment controls temperature fluctuation within ±1℃ and pressure error within ±0.5MPa.

- Dynamic Mixing: The mixing device must achieve micron-level uniform mixing.

- Functional Design: The machine should have quick start-stop and anti-curing designs to ensure continuous production. The electrical system adopts modular design, equipped with safety devices such as temperature and humidity monitoring.

- Coating Flexibility: Coating methods and minimum coating amount accuracy determine process flexibility.

- Production Capacity: Working speed, temperature, and pressure adjustment accuracy reflect production capability.

- Special Functions: Nitrogen protection systems (with oxygen content control) demonstrate optimization for PUR glue characteristics.

- Positioning Precision: With closed-loop control and visual inspection, lamination position accuracy reaches ±0.1mm.

- Substrate Adaptability: The machine can fit various base materials and achieve efficient lamination through intelligent adjustment.

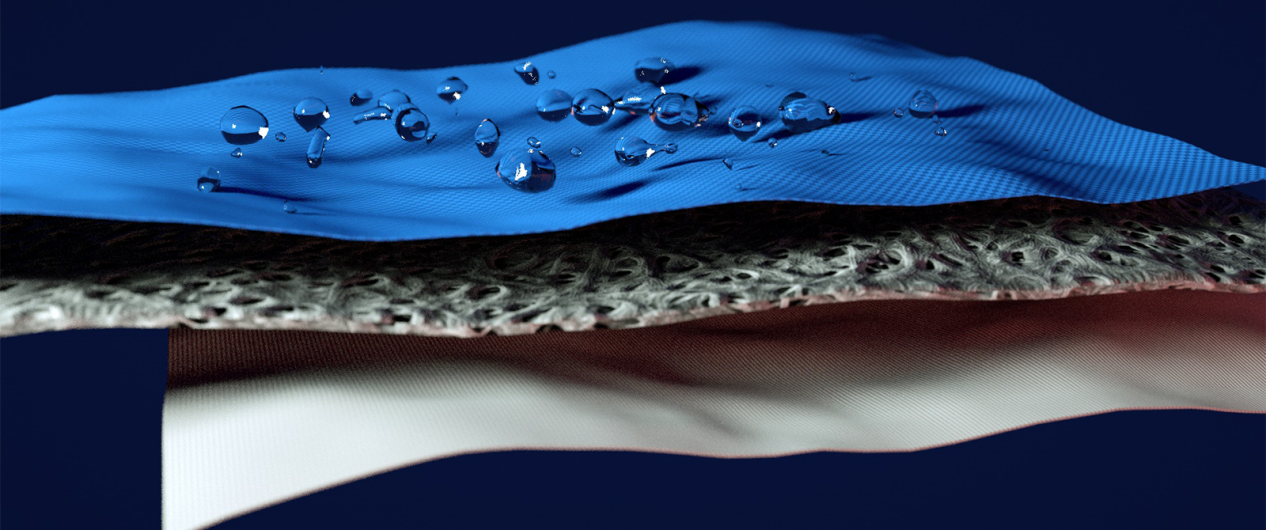

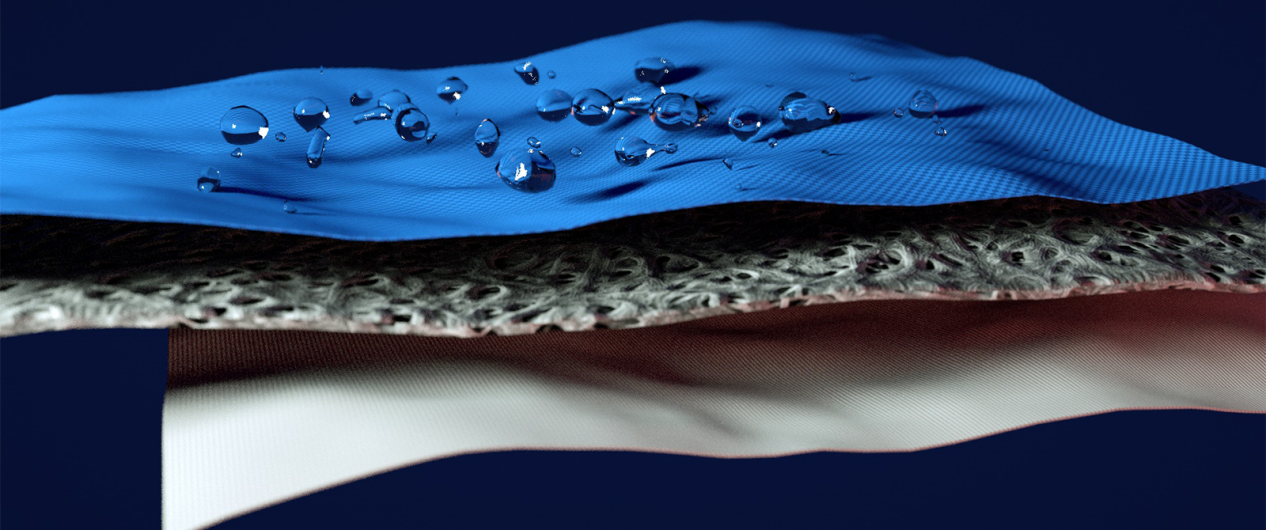

- Product Performance: After PUR glue curing, the cross-linked structure formed ensures the product’s peeling strength exceeds [specific value], with excellent temperature and water resistance.

The quality evaluation of PUR hot melt glue laminating machines requires comprehensive consideration of multiple factors. Only equipment with excellent comprehensive performance can meet the high-standard requirements of modern material lamination processing.

12 Jun

12 Jun